Faced with the accumulation ofCO2 in the atmosphere and its adverse effects, scientists are attempting to develop electrocatalytic systems for the reduction ofCO2 into carbonaceous products of interest. At the same time, this strategy aims to moderate the accumulation ofCO2 and create new channels for the production of chemical synthons, currently of fossil origin. A techno-economic analysis recently published in the journal Science[2] shows, however, thatCO2 must be converted with sufficient efficiency while minimizing device size (CO2 reduction current density of at least 300 mA.cm-2), to guarantee the economic viability of such a strategy. To reach this target, a major research effort within the scientific community is devoted to the development of nanostructured catalysts featuring maximum reaction surface area on a small electrode.

A team of scientists including Professor Marc Fontecave and his collaborators Sarah Lamaison and David Wakerley, from the Chemistry of Biological Processes Laboratory (Collège de France/CNRS)[1], have just developed catalysts enablingCO2 to be reduced at record speed for systems based mainly on non-noble metals. This breakthrough has been published in the American journal Joule.

In this vein, the team led by Collège de France professor Marc Fontecave is working to develop low-cost catalysts that are active inCO2 reduction and selective for a given product. Classically catalyzed by gold and silver, the conversion ofCO2 into CO can also be carried out on zinc, which is much less costly, but has so far been ruled out as difficult to nanostructure.

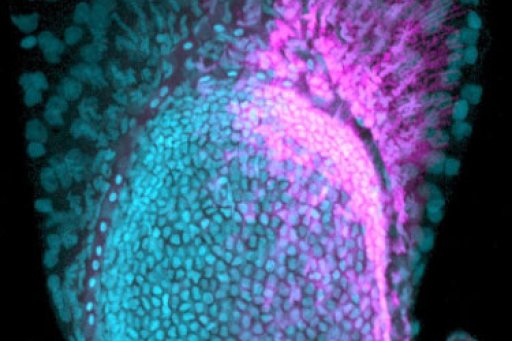

Recent work by the Collège de France, in association with the CNRS, has made it possible to overcome this obstacle by proposing an alloying strategy to generate zinc-based catalysts (>90%) with a very high specific surface area (>2000 cm2.cm-2 electrode). This strategy is based on the discovery of the promoting effect of silver on zinc growth: in very small quantities (2), these structures can efficiently convertCO2 into CO (faradaic CO formation efficiency of up to 94%) at current densities relevant to industrial application (between 200 and 400 mA.cm-2).

These performances rival those of pure noble metal catalysts, but are achieved here with low-cost, easily synthesized catalysts. All these criteria represent a further step towards the industrial-scale application of suchCO2 recycling devices.

Notes

[1] Other laboratories involved: Laboratoire de réactivité de surface (LRS, CNRS/Sorbonne Université), Institut des matériaux de Paris Centre (IMPC, CNRS/Sorbonne Université/ESPCI Paris), Chemistry of Materials and Energy (CSE, Sorbonne Université/Collège de France/CNRS), Institut de recherche de chimie Paris (IRCP, CNRS/Chimie ParisTech) and Institut de minéralogie, de physique des matériaux et de cosmochimie (IMPMC, CNRS/MNHN/Sorbonne Université).

[2] De Luna, P., Hahn, C., Higgins, D., Jaffer, S. A., Jaramillo, T. F., and Sargent, E. H. (2019). What would it take for renewably powered electrosynthesis to displace petrochemical processes? Science 350, eaav3506.